You will answer a series of questions about connected load and the transformer sizes to supply it. You will also calculate loading on different transformers under normal operating conditions.

During your career from time to time you may be expected to calculate loading at a transformer and compare it to the nameplate rating of the same. You will also be required to match the transformer kVA rating to handle the expected connected load during new installations. This module will prepare you for these tasks.

You have seen how a transformer operates via the turn's ratio to transfer power from primary voltage and current levels to secondary voltage and current levels. In the examples, power input (voltage x current) equaled power output (voltage x current). The transformer did not create power, it just transformed it for output at secondary levels.

Note: power output = power input

or

kVA out = kVA in

Transformers are built in different capacity sizes designed for particular service requirements. This is much the same as gasoline engines are different sizes depending on the job to be done - lawn mower engines, industrial engines, automobile engines. The gasoline engine is usually rated in horsepower. Transformers are rated in kVA (kilovolt-amperes). You know electric power is the product of volts times amps, thus the rating "volt-amps". Depending on the application we refer to electric power either in watts or volt-amps.

The size of a transformer is determined by the size of the customer's service requirements. A typical household service might be rated 120/240 volts, 100 amperes. This means at full load the customer requires 100 amps at 240 volts. The power needs would be 240 x 100=24,000 volt amps or 25 kVA. A 25 kVA transformer would easily supply this load. Similarly, a service rated 240 volts; 200 amperes would have a power capacity of 240 x 200 = 48,000 volt amps or 48 kVA and would need a 50 kVA transformer.

When a customer chooses a service size of 60A, 100A, 200A, or 400A, many factors will have been considered such as size of the building, total connected load, heat loss, type of heating, etc. Generally we don't run all our electrical equipment at any one time. Having a 100A or 200A service does not mean the constant current draw always equals the service size. The service size will handle a specified load. Yet most households rarely exceed half the capacity of their service. The larger the service size, the larger the panel box and therefore more individual circuits can be run without overloading a circuit or doubling up wires at the panel's breakers or fuses. The service size chosen generally allows for future expansion.

In subdivisions, ten secondary 100A services will often be run from one 100 kVA transformer. In theory the total connected load would be 1,000 amps. At 240 volts the power would be 240,000 volt amps or 240 kVA. How can a 100 kVA transformer supply all of these customers instead of a 240 kVA?

As in the individual customer supplied by one transformer, all ten customers on the 100 kVA will likely not operate every appliance and light bulb they own 24 hours a day. Different families will do things at different times. Supper is not served at 5:00 pm in every household; the washing is likely not done at the same time on the same day; whatever the power needs of one household, they are not likely the same as or happen at the same time as every other house.

This diverse use of electricity in different homes means the 100 kVA is not likely to be overloaded at any one time or for any length of time. Knowing this, the utility applies what is called Diversity Factor, which reflects anticipated maximum connected load to determine transformer size. Many utilities purposely load transformers to 140% of their capacity. While this may shorten the transformer's life, the capital cost savings are substantial. A 50 kVA cost much less than a 100 kVA. Good business sense dictates equipment be used to capacity.

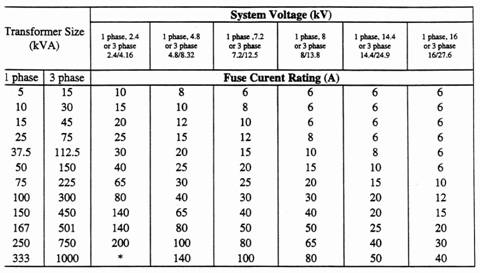

Whenever you are installing a transformer the fuse size for the installation is taken from your Utility's Distribution Standards. Transformer fusing sizes allow for some overloading and transient short circuits on the secondary side. As a rule, transformers are fused higher than the full load current. An example fusing table, found in module 12, is for use as a Standard when installing a transformer during your training here. Your Utility's Standards may vary somewhat from this and you should you follow it when at home.

Using the fusing table in module 2.12 a 25 kVA transformer connected to a 2400 volt primary supply should be fused at 25 amps. This transformer loaded to 100% capacity would draw 10.4 amps.

P = E x I

I = P/E = 25,000/2400 = 10.4 amps

If the transformer was fused at 10 A, any slight overload on the secondary side would cause the transformer fuse to blow. This results in a power interruption and a trouble call. Likewise, if during a windstorm, secondary wires blew together briefly, the extra short circuit current drawn would blow the fuse. If the transformer fuse is larger than full load current of the transformer, it provides a buffer against brief overloading and transient secondary shorts.

The full load current of the 25 kVA at 2400 volts is 10.4 A.

The full load current of the 25 kVA at 4800 volts is 5.2 A

I = P/E = 25.000 = 5.2A

4,800

The full load current of the 25 kVA at 7200 volts is 2.5 A

I = P/E = 25.000 = 3.47A

7,200

The 25 kVA transformer at 2400 V, 4800 V, 7200 V supplies the same amount of power.

2400 x 10.4 =24,960 VA or 24.96 kVA (25 kVA)

4800x 5.2 =24,960 VA or 24.96 kVA (25 kVA)

7200 x 3.47 =24,934 VA or 24.98 kVA (25 kVA)

When the voltage was doubled, 2400 V to 4800 V, the primary current was decreased by half. When the voltage was tripled, the primary current was decreased by one third.

1. In theory P = E x I; calculate the kVA transformer size required for the following secondary services:

a) 240 volts, 100 amps

b) 240 volts, 125 amps

c) 240 volts, 200 amps

d) 240 volts, 400 amps

2. In practice, a transformer kVA rating might be smaller than a customer's theoretical service kVA rating. Why might this be?

________________________________________________________________________________________________________________________________________________

3. Does a customer's service size mean the customer must draw that much power continuously?

________________________________________________

4. Distribution transformers will stand some overloading without damage.

a) True b) False

5. Transformers are fused _______________________________

than their full load current.

6. The full load primary current of a 25-kVA transformer operating at 2400 volts would be

____________________________ amps.

7. The full load primary current of a 100 kVA transformer operating at 4800 volts would be _________________________ amps.

8. If the full load primary current of a 50-kVA transformer operating at 2400 volts is 20.8 amps, and a 50-kVA transformer operating at 4800 volts is 10.4 amps, then the full load current of a 50 kVA transformer operating at 7200 volts would be _________________ amps.

Check your answers with those at the end of this module. If you had any incorrect answers, read the information in this Section again or talk to an instructor.

You know how a transformer size is chosen to provide power for service requirements, and how they are fused to handle brief overloading and transient short circuits. Now let's look at how the transformer provides power to a customer's service at 120 volts and 240 volts.

A typical household service requires 120 volts to operate equipment such as lights, kettles, vacuum cleaners, hair dryers, toasters, etc.; 240 volts to operate water heaters, ranges, water pumps and clothes dryers. The standard distribution transformer has two 120 volt secondary windings, providing 240 volts if connected in series. The center tap, or mid-point connection (X2) of the transformer is connected to ground potential and is called the neutral.

The following diagram shows the two secondary windings connected to supply both 120 volt and 240 volt loads.

Figure 1

In Figure 1 there are two 120 volt loads. One is connected between the live leg X1 and neutral X2, with the other between X2 and X3. Also shown is a 240 volt load connected between the two live legs X1 and X3.

A 120 volt appliance has a neutral since it requires a potential difference of 120 volts. This is obtained between the grounded neutral X2 and either X1 or X3 since each of the secondary windings will supply 120 volts. A 240 volt appliance requires a potential difference of 240 volts. This is obtained between X1 and X3 since the two secondary windings are in series, 120 + 120 = 240 volts. A 240 volt appliance does not need a neutral to operate.

Let's look at how current flows in each of the 120 volt and the 240 volt appliances. Remember, current flows from negative (excess of electrons) to positive (deficiency of electrons). We are looking at an instantaneous current flow since in AC, polarities change twice during each cycle and operates at 60 cycle per second.

Figure 2 shows two 120 volt loads connected to a transformer. The instantaneous polarities of the windings are indicated and arrows show the direction of current flow.

Figure 2

Load A has current supplied by the secondary winding on the left. Since we are looking at instantaneous polarity, current leaves the transformer from X3 bushing, passes through load A and re-enters the transformer completing the circuit through X2. We know during the next half of the AC cycle, the direction of current would be reversed. Even though the X2 is grounded, and at zero volts, current still flows through it to complete the circuit.

Load B current is supplied from the secondary winding on the right. Current for this load leaves the transformer from the X2 bushing (negative end of the winding on the right), passes through load B and enters the transformer through X1 bushing completing the circuit.

Let's put some resistive values on load A and B to calculate the amount of current flowing through them. In Figure 3 if the loads were balanced (both the same value), the diagram would look like this:

Figure 3

With 12 ohm loads, 10 amperes of current will flow in each circuit. The clip-on reading around the lead from the X3 bushing will read 10 amps; around the lead from the X1 bushing the reading will also be 10 amps. How much will the clip-on reading around the lead from X2 be? The reading will be 10–10 = 0 amps. These two 120 volt circuits with 10 amps of current flowing in each constitute a balanced load at the transformer.

With a balanced load there is no effective current flow through the neutral.

Figure 4 is an example of an Unbalanced load, where the two secondary windings are loaded to different current values.

Figure 4

|

Load A is 10 ohms resistance and load B is 15 ohms.

Using Ohm's Law we can calculate how much current flows through each load.

Load A current:

E = I x R

I = E

R

I = 120

10

= 12 amperes

Load B current:

E = I x R

I = E

R

I = 120

15

= 8 amperes

A clip-on ammeter would read 12 amperes on the lead from X3 bushing and S amperes on the lead from X1 bushing. How much would the ammeter read on the lead from the X2 bushing?

From load A there is 12 amps going into the X2 bushing; for load B there are 8 amperes coming from the X2 bushing. The net effect read by the clip-on ammeter would be 12 - 8 = 4 amps.

Figure 5

Figure 5 also shows an unbalanced secondary transformer load. Load A might represent a toaster drawing 12 amps; load B might represent a set of lights drawing 6 amps. Each load is connected across 120 volts and functions properly.

Figure 6 shows what happens if the neutral of the service breaks or is improperly connected.

Figure 6

|

With the neutral "open" or broken, the 10 ohm and 20 ohm loads are put in series for a total resistance of 30 ohms. Without a neutral, there will be 240 volts potential across the loads. From Ohm's Law we can determine what will happen:

E = I x R

I = E

R

= 240

30

= 8 amperes

There will be 8 amps of current flowing in the circuit. Load A originally needed 12 amps to make it operate. It is now receiving only 8 amps. Consequently it will not operate properly. Load B needed only 6 amps to operate but is now supplied with 8 amps. This higher current will cause the lights to burn very bright and to burn out quickly.

Periodically you may have to connect or disconnect a secondary service where you can't get into the building to open the main switch to drop the secondary load. To prevent damaging customer's equipment, if in fact there is an unbalanced load connected, always connect the neutral lead first, then the live leads; when disconnecting a service always disconnect the live leads first and the neutral lead last.

Here is another review to monitor your progress.

1. The X2 bushing of a distribution transformer is the center tap or mid-point connection of the two secondary windings. It is grounded to keep it at ______________________.

2. Connect the following loads to the distribution transformer with lines to represent wires.

|

3. When connecting a secondary service alive, always connect the ____________________ lead(s) first and then the

_____________________ lead(s).

4. When disconnecting a secondary service alive, always

disconnect the ___________________ lead(s) first and then the _____________________ lead(s).

5. The following diagram is an example of a _________________ load. (balanced, unbalanced)

6. What is the secondary winding full load current

in the diagram

of question 5?

__________________________________________________

7. What is the primary winding full load current if it is 2400 volts in question 5?

___________________________________________________

8. What is the primary winding full load current if it is 4800 volts in question 5?

___________________________________________________

9. What is the

primary winding full load current if it is 7200 volts in question

___________________________________________________

Check your answers with those at the end of this module. If you are experiencing any difficulty read this section again or ask your instructor for assistance.

Note: Current and voltage reading on each phase should be taken

simultaneously, if possible, so that load shifts will not give

inaccurate loading.

The load the transformers will be required to carry will be the amount of resistance (load) in the secondary circuits, which supply a certain area. The combined amperage requirements of each house, such as lighting, heating, appliances, hot water, etc., which all have resistance and will determine the current (load) that the transformer will be required to carry.

EXAMPLE: There is a load requirement of 200 amp per leg on a 240-Volt circuit or 400 amp on a 120-volt circuit.

Therefore: - 240 V x 200 Amp = 48,000 Volt Amps

-120 V x 400 Amp = 48,000 Volt Amps

=48kVA

Transformer Required =50 kVA Volt

Most transformers may be loaded to approximately 140% of their nameplate rating, (loading beyond the 140% may be permitted) providing certain conditions exist. Two of these conditions are, the ambient temperature and the duration of the overload conditions.

SINGLE PHASE 120/240 VOLT TRANSFORMER LOAD

Measure the current on one phase at the transformer bushing (x1) and multiply by the phase to neutral voltage of that phase. Do the same on the other phase (x3) bushing (Figure 7).

Figure 7

|

Formula for calculating total transformer kVA loading is:

Total kVA = (V1 x A1)+(V2 x A2)

On a single phase 120/240 Volt transformer, calculate the total kVA loading on the Transformer using the following diagram and information (Figure 8).

Figure 8

Total Amperage Reading at X1 is l8 A + 12A = 30A

Total Amperage Reading at X3 is 12A + 12A = 24A

Formula (V1 x A1) + (V2 x A2) = Total kVA

(120 x 30)+(120 x 24) = Total kVA

Total kVA = 3600+2880

= 6480 Volt Amps 6.48 kVA

=6.48 kVA

Add amperages from X1 and X3 together and divide by 2. Multiply result by 240 Volts

Example: 30 + 24 = 54 AMP

54 =27

2

27 X 240 = 6480 Volt Amps

= 6.48 kVA

1. a) 24kVAor25kVA

b) 30 kVA or 374/2 kVA

c) 48 kVA or 50 kVA

d) 96 kVA or 100 kVA

2. Customer not likely to have every piece of electrical equipment operating at once, or diversity of use.

3. no

4. true

5. Heavier

6. 10.4 A

7. 20.8 A

8. 50,000 = 6.9 A

7,200

1. ground potential

2.

2.

3. neutral, live

4. live, neutral

5. unbalanced

6. 16a

7. 1.6a

8. . 8a

9. .533a

INSTALL SINGLE-PHASE DISTRIBUTION

TRANSFORMER

You will answer a series of questions regarding the procedure for installing single-phase transformers. Just a reminder some Pike Electric, Inc. customer's standards may be different from the following that you will learn.

In this module you will learn how to install, wire and connect a single-phase distribution transformer following the Standard Drawing in this module. This drawing is standard for all voltages up to and including 14.4/24.9 kV.

Transformers are one of the most important pieces of equipment used in the distribution of electric power. They raise and lower voltage and current levels to allow electric power to be transmitted great distances and also be used in household and industrial settings. A large portion of your work as a lineperson will deal with the installation of, removal of, and servicing of distribution transformers. In this module you will learn a safe installation procedure to put a single-phase distribution transformer into service.

Transformers are subject to various types of damage. Most of these result from poor handling and transporting practices. Some of the most common damages are:

- Porcelain bushings being broken or cracked due to rough handling or over tightening of the bushing connector.

- Tank damage in the form of scratches, dents or punctures. Scratches cause premature rusting of the tank. Dents reduce clearances between line internal windings and the grounded tank. Punctures allow the insulating/cooling transformer oil to expel causing rapid deterioration of the transformer.

- Gasket damage at the lid and bushings often caused by improper alignment and tightening allows moisture to enter the tank. This moisture destroys the insulating qualities of the oil and accelerates rust.

- Core damage often results

when the mounting brackets break due to a drop or rough handling. Also exercise

care when

lifting the lid on top mounted bushing transformers to ensure

the ends of the primary lead(s) are not

pulled out of the core.

Transformers are delivered from the manufacturer in wooden crates. They should be left in the shipping crate until erected. If the crate must be removed before transporting, secure the transformer by tying to prevent any movement on the truck.

Before putting a transformer into service it should be checked carefully for damage. Inspect it for dents and scratches to the tank, oil leaks due to damaged gaskets and the bushings for broken or missing connectors. An internal check of the transformer would be required if the tank was dented, bushing cracked or gaskets damaged.

TRANSFORMER SELECTION - NAME PLATE DATA

Interpretation of the following data found on the transformer nameplate is essential to its proper selection and connection:

- kVA or capacity in thousand volt-amperes.

- HV, the voltage to be applied across the high voltage coil must be matched to the nameplate rating. Some transformers have two or more tap settings on the primary coil allowing their installation on different primary voltages. If this is the case ensure that it is placed on the correct setting.

- LV, the voltage value required across the secondary coil or coils.

- Insulated for Wye connection. This indicates that one high voltage terminal should be grounded and the other connected to a phase, with a phase to ground voltage equal to the HV rating.

- The A, B, C, and D connections to the X1, X2, X3 secondary bushings. These provide a means of placing the secondary coils in series or parallel to give 120 V, 120/240 V or 240 V output.

- Hz, hertz or frequency, whether the transformer is built to operate at 25 or 60 cycle power.

- Serial number and name of manufacturer, usually recorded to maintain a reference as to the location of each transformer.

- Weight, must rig to handle.

- Number of liters of oil installed when manufactured.

Although many variations of single-phase transformer installation may be found throughout your utility yet there is a preferred standard to be used. Figure 1 shows this installation and is the one you will use during this session. The transformer is direct pole mounted. The switch and arrester are mounted on a combination bracket and placed a safe distance down from energized conductors. The system neutral and all secondary conductors are below the transformer. This allows safe and convenient disconnection of the secondary leads from the bus to prevent backfeed when working on an isolated transformer.

To maintain safe working clearances from energized primary conductors, the transformer is mounted a considerable distance down the pole.

Note: Existing installations with reduced clearances may require protective cover-up to be applied to the energized

conductors in order to remove equipment and hardware.

Figure 1

Note: This is an example of some customer's measurements. Each customer may vary different measurements, check your customer standards.

To avoid as much as possible, interruption to services for

transformer maintenance or replacement, etc., live line clamp

connections (that can be operated with a live line tool) shall be

used on all phase leads and stirrups installed on the line conductors. The stirrup prevents damage to the line conductor from arcing, when the live line clamp is installed or removed. Also, line vibration may loosen the live line clamp over a period of time causing a loose/high resistance connection, which would eventually burn off the live conductor if the live line clamp is not installed on a stirrup. The live line clamp may vibrate loose in time even if it is attached to a stirrup, but damage would be confined to the stirrup bail, nor the conductor itself.

The lead from the live line clamp to the switch, the lead from the primary neutral to the transformer, and the grounding lead, for transformers up to 167 kVA, will be copper conductor.

The primary lead from the load side of the switch to the transformer high voltage bushing can be copper transformer drop wire.

Some customer's standards require covered wire that is rated, depending on the voltage under no circumstances shall it be considered as insulated or safe to touch. The polyethylene covering is a form of bird proofing the wire to prevent an outage should a bird roost on the wire and peck at the transformer case. The poly covered wire may be substituted with bare copper.

Secondary "drop" leads from the transformer shall be sized to a percentage of the transformer rated capacity. Many of our customer have a chart outlining the secondary lead size for each transformer, based on 140% of the transformer capacity (kVA).

A ground strap is often supplied on new transformers, which connects the mid point, X2 secondary bushing of the transformer secondary coils, to the transformer case. This ground strap positively grounds the neutral bushing (X2) keeping it at ground potential, since the transformer case is connected to the ground lead.

Most new transformers are supplied with only one insulated high voltage bushing and a stud welded to the transformer case labeled H2. One end of the transformer primary winding is terminated at the insulated bushing, the other end is terminated by a connection inside to the transformer case. This, in fact, makes the whole transformer case, the H2 primary neutral terminal. The H2 stud must be grounded to the system neutral. There is a real hazard of the transformer case becoming alive at line voltage should the H2 lead break or burn off. Consequently, it is important the transformer be grounded at 3 places, the H2 stud, the case ground and by connecting the secondary neutral lead to the system neutral.

Note: With one primary bushing three separate ground connections required.

Transformers require protection from high voltage and current surges.

Lightning arresters were discussed in a previous module. They vent high voltage surges to ground so the high voltage does not pass through the transformer causing damage.

Figure 2

|

The lightning arrester is connected to the ground rod that has a resistance of 25 ohms or less. The line side lead of the arrester is usually connected to the line side of the fused cutout. However, on 7.2/12.5 KV kV systems it is common to connect the arrester line side lead to the load side of the fused cutout switch. A 15 kV rated arrester is used on 7.2/12.5 kV systems and there have been some problems with these exploding as soon as they are energized. If this arrester were connected to the line side of the switch, it would energize as soon as the lineperson made contact between the live line clamp lead and the stirrup. The lineperson's full attention is focused on the live line clamp and they would be vulnerable to injury should the arrester fail. To protect against this possible hazard, if the arrester lead is connected to the switch load side, since the cutout is open, the live line clamp may be installed on the stirrup without energizing the arrester. Now the lineperson can move away from the hazard area or reposition himself on the pole away from the arrester to close the switch.

To protect the transformer from over current, a fuse in the switch cutout is used. If a short circuit or extreme overloading occurs on the transformer secondary leads or inside the transformer, the high current will melt the fuse. This isolates the transformer and the associated problem from the main line. The fuse and switch are cut in the primary drop lead between the main line and the transformer. If the fuse blows, the fuse holder drops open from released spring tension or gravity, giving a visual indication the fuse has blown.

NOTE:

Check the power customer for the proper fusing chart.

Example of a fuse chart:

TRANSFORMER PRIMARY FUSE SIZES

TRANSFORMER PRIMARY FUSE SIZES

Fused cutouts also provide a way to physically isolate the transformer from the line for maintenance, replacement or repairs. The cutout is simply pulled open with a switch stick, and then the live line clamp is removed.

On some customer systems, a current limiting type fuse is often installed on the line side of the transformer switch.

High fault-energy as experienced on phase to ground short circuits often results in "catastrophic" failure of a transformer. This is a failure where the reaction to an arching fault results in:

1. The cover being blown off;

2. The tank splitting;

3. Fire occurring;

4. The expulsion of a piece of the equipment or oil.

A cutout fuse alone cannot prevent this happening as it takes too long to operate. A current limiting fuse in series with the cutout though prevents such a failure in most cases. In cases of a transformer fault, the energy consumed by the current limiting fuse converts the silica sand inside the fuse to glass.

The resulting dielectric path is sufficiently strong to interrupt current flow. Fault current levels are low enough on most distribution systems that current limiting fuses are not required. They are a relatively expensive one-shot device used only where necessary. From your understanding of Ohm's law and the relationship of voltage, current and resistance, you can see the higher the voltage supplying a short circuit, the greater the amount of current. High voltage and high current produce very high energy/power which can lead to transformer damage, if a current limiting fuse is not used.

Lightning arresters, primary and secondary neutral bushings and transformer cases must all be grounded. A ground wire of at least #4 copper is used to tie all these components to the system neutral and brought down the pole to a driven ground rod (Figure 3). Some customer requires that Pike Electric megger the resistance of each ground rod to ensure it is 25 ohms or less. If the resistance is about 25 ohms, an attempt to lower the resistance can be made by driving up to three ground rods at 10' apart all connected by the ground wire. If after this the resistance is still above 25 ohms no further ground rods are used. Many utilities don't measure each ground rod's resistance, as measurements taken over a period of years indicates the earth within their boundaries provides adequate low ground resistance.

Figure 3

|

The low resistance of the ground rod connection fulfills a two-fold purpose:

1. It positively grounds the system neutral and secondary neutral to ensure they are at ground potential.

2. It ensures positive action of the lightning arrester during voltage surges.

There are many methods of raising transformers to their mounting location on the pole. The method used is governed mainly by accessibility of vehicle equipped booms and aerial devices. Whichever method is used, it is imperative the lineperson be aware of his/her personal clearances and those of the hoisting equipment when working under live apparatus.

If rope blocks are used to raise the transformer, a transformer gin of adequate rating must be used and rigged as shown in Figure 4.

Figure 4

The rope and block sizes used in the set of rope blocks must also be of adequate strength to handle the weight to be lifted. In your Level 1 lines manual "Rigging" module you learned how to calculate the working load limits (WLL) of various ropes and how to calculate the mechanical advantage of rope blocks. Work through the following example as a quick rigging refresher.

A set of three sheave blocks containing 1/2" polypropylene rope is used to raise a 500 lb transformer. The blocks are attached to the pole by a transformer gin and to the transformer using a 2" nylon sling in a basket configuration (Figure 4).

trans pole gin - 1200 lbs

crossarm gin - 2000 lbs

3 sheave 4" blocks - 2300 lbs

2" nylon slinging in a basket configuration - 13,800 lbs

Mechanical advantage is calculated simply by counting the number of ropes that go into and come out of the moving or running block (the moving block in Figure 4 is the one connected to the transformer).

Upon close inspection you'll see that six ropes either go into or come out from this moving block, therefore the mechanical advantage of the rope blocks in this configuration is six.

Friction also plays a part in the calculation of load on the fall line of the blocks. When a rope is bent around a sheave at an angle greater than 90° (as in the case in a set of blocks) friction adds an additional 10% increase in weight to be lifted. A set of three sheave blocks would have six individual sheaves adding a 10% increase in weight per sheave, resulting in a total of 60% increase in the weight to be lifted.

Placing all this information into a formula we now have a means

of calculating the pull on the fall line.

Pull on fall line = weight to be lifted + % friction

mechanical advantage

PFL =500 lbs +300(60% of 500

friction)

6 (MA)

= 800

6

= 133.3 lbs

- compare this weight to the WLL of the 1/2" poly rope contained in the blocks

WLL 1/2" poly equals

= 4 x 4 (sq the 1/8" of rope size) x 20 (mult. For poly rope)

=320 lbs

Therefore the rope size of 1/2" poly is adequate.

- Compare the total weight at the attachment point of the blocks to the WLL of the davit.

Total weight at point of attachment equals

Weight to be lifted + pull on fall line

=500lbs+133.3lbs

=633.3 lbs

Either davit may be used.

- Compare the weight on the attachment sling to its

WLL.

Slings should not be used with a sling angle less than 30° (measured from the horizontal). We therefore must determine the weight that will be exerted on the sling. Figure 5 shows how the weight on the sling increases as the sling angle decreases. Notice that at 30° the total weight on the sling doubles.

Figure 5

Therefore the total weight exerted on the 2" nylon sling in our example would be 1000 lbs. This Likewise is well within the WLL for this sling.

If a polypropylene rope sling were used instead of the 2" nylon web sling, it would have to be 1" in diameter to handle the weight safely.

Note: A sling rated twice the weight to be lifted must be used.

The job of installing a single-phase transformer should start at the top of the pole and work downward:

- Determine the phase the transformer will be fed from. Install a stirrup (some customers required) using live line techniques on the back side of the pole (opposite side to the transformer).

- Measure down from either the top of the pole, the cross arm through bolt, the top bolt of the improved appearance bracket or from the insulator at a deadend structure, the required distance for the combination switch and arrester. Bore the hole for the switch bracket at right angles to the line.

- Measure down from the switch bracket hole the distance required to the top hole of the transformer. This distance varies with the framing design on the pole and is found in Figure 1. Bore the hole parallel to the overhead line boring from the face of the pole. The distance to the second hole is determined by the transformers size and the resultant kick distance.

The mounting bracket spacing most often will be 14.5" for transformers up to 25 kVA and 21.5" for all those larger. Nearly all transformers now required 3/4" bolts for mounting to the pole.

- Measure from the bottom-mounting bracket of the transformer down to the bottom of the tank. Add 30 cm/ 12 inches to this measured distance and bore a hole at right angles to the line for the neutral attachment.

- Measure and bore all other holes required for service racks or other hardware as dictated by your Utility's Standards. Send

the drill to the ground.

- Relocate the neutral to its new location and clamp/tie in.

Note: If the primary neutral is located on the crossarm, it may stay on the crossarm. A stirrup(may) will be installed using live line techniques and the transformer primary neutral lead installed with a live line clamp using a live line tool.

- Assemble and mount the combination switch and arrester on the pole and secure. The switch should be angled away from the transformer towards the stirrup (approx 45°)• Measure the switch lead from the stirrup to the top of the switch using a live line tool. Cut the lead to length and park the live line clamp so as to allow easy access of the shot gun stick when energizing the transformer later. The fuse barrel must not be installed at this time.

- Run the copper ground up the pole and attach it to the flex copper lead from the bottom of the arrester. Form a loop at the neutral, staple, remove all slack and attach to the ground rod.

The connection to the system neutral may be made only after the ground rod has been connected.

- Install transformer bolts loosely in the pole in readiness for the transformer.

- Ensure the required data from the nameplate has been recorded.

- Send the transformer aloft by means of a digger derrick, place on bolts and tighten. Where accessibility is limited rope blocks may be required to install the transformer. Ensure all rigging obtained to install the transformer in the field is adequate to handle its weight.

- Ground the common bushing first to X2 bushing to common neutral. Then proceed to ground the transformer tank as shown in figure 1

- Wire the transformer as shown in Figure 1. Start at the top of the transformer and work down to the secondary. To avoid the hazard of backfeed the secondary lead connections to a service or bus wires must be made only after all other primary and ground connections have been completed

- Install the primary switch lead to the line stirrup using at least a 8' shot gun stick (live line tool).

- Install the fuse barrel into the switch.

- Close the cutout fuse barrel with the switch sticks.

- Check the transformer secondary voltage with a voltmeter to ensure the transformer is operating correctly. If ok open the cutout fuse barrel de-energizing transformer.

- Install the service cable into secondary bushings and energize transformer.

.